Custom Scouts

Original Replica - FULL Width "Time Saver" Inner Floor Pan

Original Replica - FULL Width "Time Saver" Inner Floor Pan

Couldn't load pickup availability

Why buy Custom Scouts floor pans for your Scout II or Traveler? Because they fit and save you time!!!

Our revolutionary "Original Replica" floor pans are designed from the ground up with industry-first materials*.

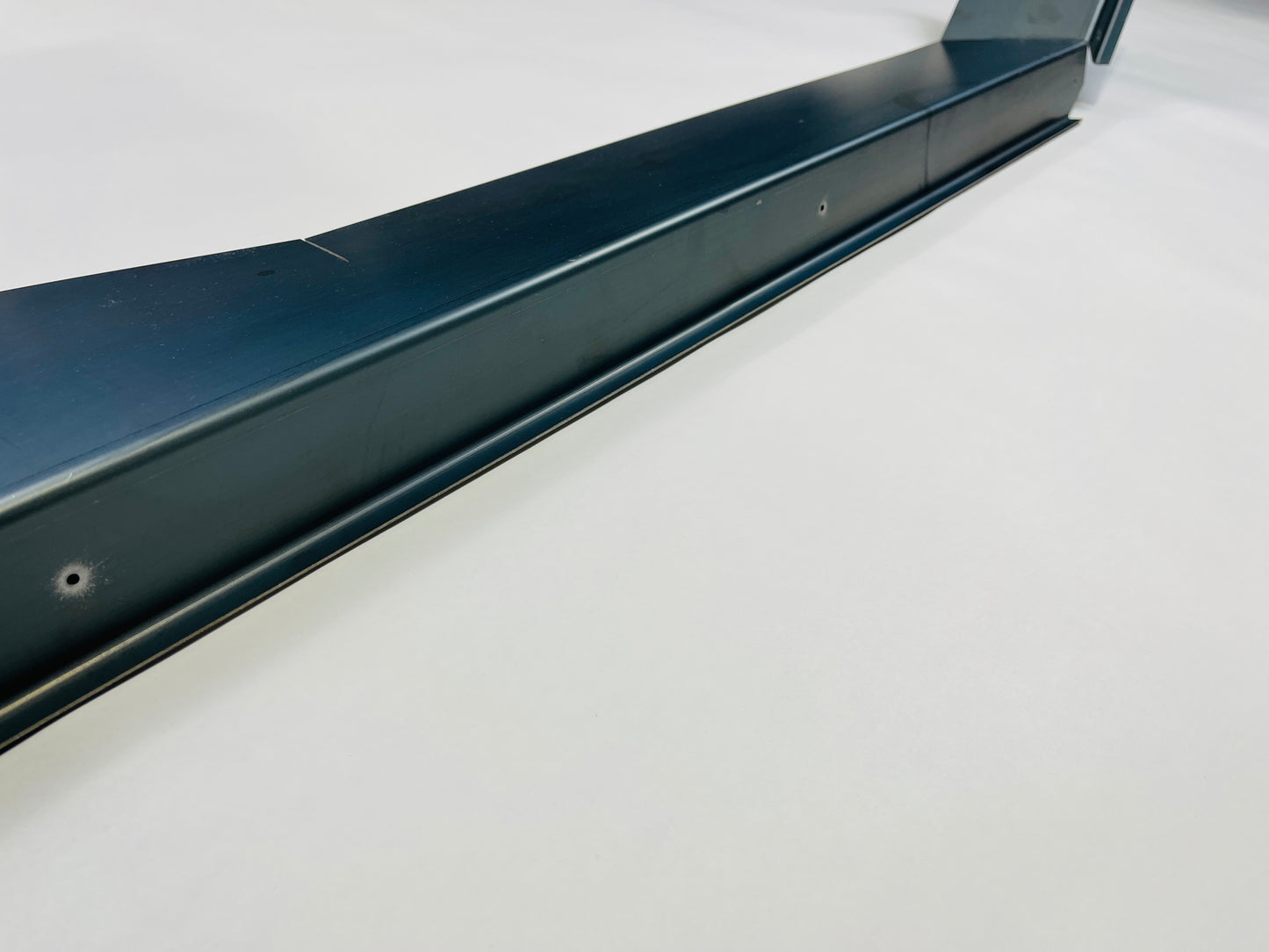

These "Full Width" Inner floor pans include the pinch weld seem/flange that runs front to back along the transmission tunnel. This flange is often rusted out and in need of replacement on many Scout II and Traveler/Terra's. Replacement of the flange is not easy to make look right without the help of panels like this one. You either spend your money on trying to make your own, wasted material, less than professional finished look, or just buying the right parts to begin with. Save the time and cost on trying to make your own and invest in these full width floor pans. We promise you will thanks us for giving you good advise!

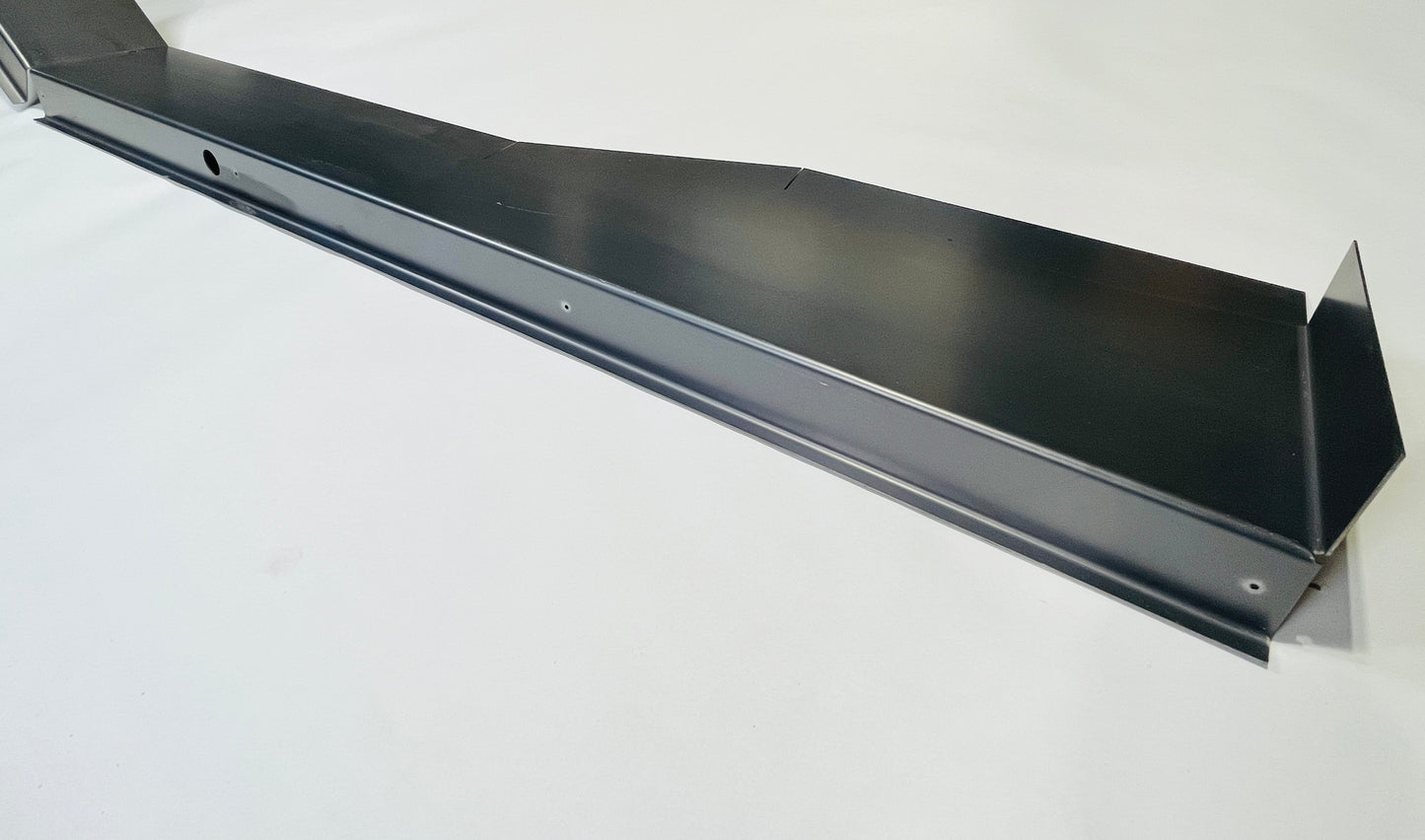

Not only have these floor pans been designed to fit out of the box better, but they are also all pre cut with spot weld, seat base and seat belt holes, saving you time on install. They have been designed to fit properly with no cutting and re welding to make them fit. We offer our laser cut, CNC formed Scout II and Traveler replacement floor pans in 2 versions; mild steel and soon in our industry-first 304 stainless steel, a series we nicknamed “zero rust”. And yes you can weld 304 stainless steel with a regular MIG welder and you can weld 304 stainless steel to mild steel. You can also install your floor pans with 3M structural adhesive.*

Why buy new floor pans? Let’s face it, If you have a Scout, your floors are either rusted through or are severely weakened due to the surface rust on them already. Remember your seats and seat belts bolt to your rusty floor pans.

Save the time and metal working for things that matter on your Scout and buy parts that fit!

*Until now the only replacement parts for Scouts are galvanized coated mild steel. If this galvanized coating Is not removed before welding, the coating will emit fumes during welding and can cause serious short term and long term health problems. The rest of the coating will be removed in order to PROPERLY prepare for paint, through sanding or other abrasive blasting.

*If you use structural adhesive for installing your floor pans, we would use bolts or pop rivets under the seat area to secure the pan to a crossmember that is welded to the body pinch weld and inner rocker. In addition if using this type of adhesive you need to clamp or put weight on the panel while it is drying so that it cures properly. Always follow the package instruction for your adhesive.

Product Details

Product Details

Laser cut and CNC formed for repeatable accuracy and fit

Available in mild steel and our “zero rust” 304 stainless steel

No galvanized coating that needs to be removed and no health concerns with welding galvanized steel

Left and right pieces sold individually

Fits 1971-1980 Scout II or Traveler with no prior modification

Available exclusively from Custom Scouts

“Zero Rust” Benefits

“Zero Rust” Benefits

Do the job once and never look back again. Ever!

Adds value to your restoration by resisting rust like nothing else.

Easy to weld.

Weight & Dimensions

Weight & Dimensions

Mild Steel

55 × 17.5 × 4.13 in

17.6 lb

Stainless Steel

55 × 17.5 × 4.13 in

13.5 lb

Share

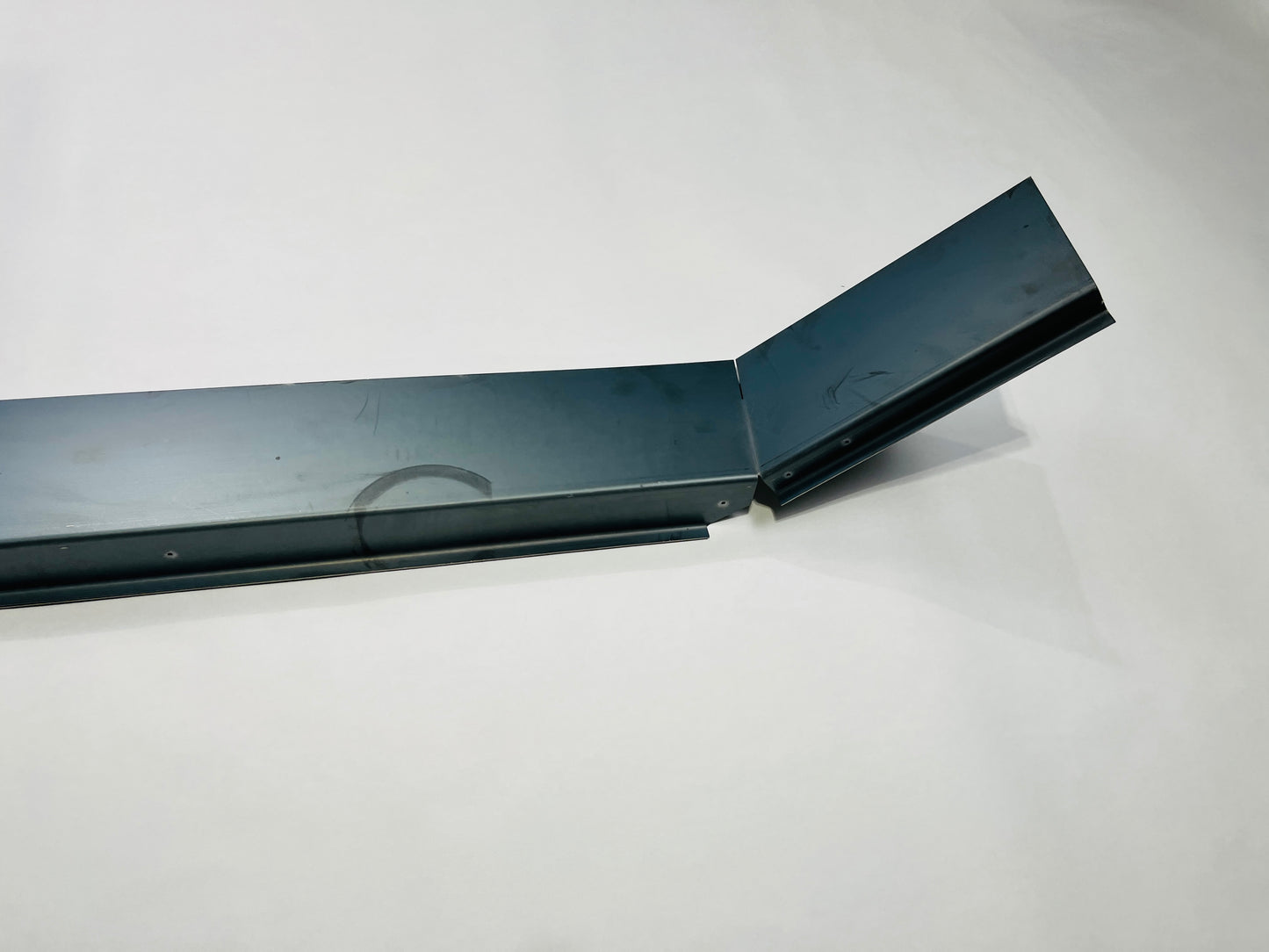

Assembly made easy

Weld yourself a finished product.

All our products are made quick to assemble and install with our intuitive design and easy to read instructions.

1. Align the tabs

2. Weld together

3. Install and done

Let's keep in touch.

Be the first to know about new parts and products and exclusive offers. Also, receive 5% off your next order when you sign up.