Custom Scouts

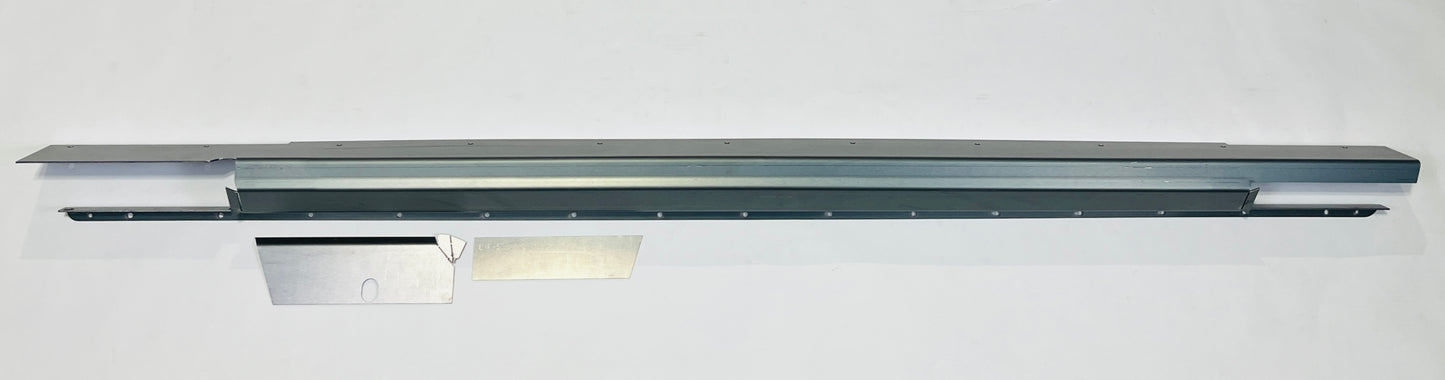

Scout II and Traveler Standard Width Sheet Metal Package

Scout II and Traveler Standard Width Sheet Metal Package

Couldn't load pickup availability

HERE IS THE DISCOUNTED PACKAGE!!

Get the most bang for your restoration buck with our discounted standard width sheet metal packages. Available in mild steel and soon in our rust resistant "zero rust" 304 stainless steel. Our products are durable, weldable and ensure that your Scout performs in all terrains, beyond the life of the vehicle.

Standard vs. Full Width:

—-Standard width—-Front to back butt weld needed to join your original floor pan pinch weld to this new floor pan, from the cargo area to the firewall.

—-Full Width—-No butt weld needed. Built in original pinch weld eliminates time and welding for a factory look in less time.

Each mild steel or stainless steel package includes:

Original Replica - Standard Width "Time Saver" Outer Floor Pan Left and Right

Original Replica - Heavy Duty Full Front Cab Mount Left and Right

Original Replica - Heavy Duty Outer Rocker Panel Left and Right

Half Kick Panel Left and Right

Door Pillar Inner Rear Gusset Left and Right

Original Replica - Heavy Duty Front Body Cab Mount Wedge Left and Right Original Replica - Heavy Duty Inner Rocker Left and Right

BASICALLY INCLUDES EVERYTHING NEEDED TO REPLACE THE SHEET METAL FROM THE FLOOR TO THE TOP OF THE KICK PANEL.

*Until now the only replacement parts for Scouts are galvanized coated mild steel. If this galvanized coating Is not removed before welding, the coating will emit fumes during welding and can cause serious short term and long term health problems. The rest of the coating will be removed in order to PROPERLY prepare for paint, through sanding or other abrasive blasting.

*If you use structural adhesive for installing your floor pans, we would use bolts or pop rivets under the seat area to secure the pan to a crossmember that is welded to the body pinch weld and inner rocker. In addition if using this type of adhesive you need to clamp or put weight on the panel while it is drying so that it cures properly. Always follow the package guide lines of the adhesives you are using.

Share

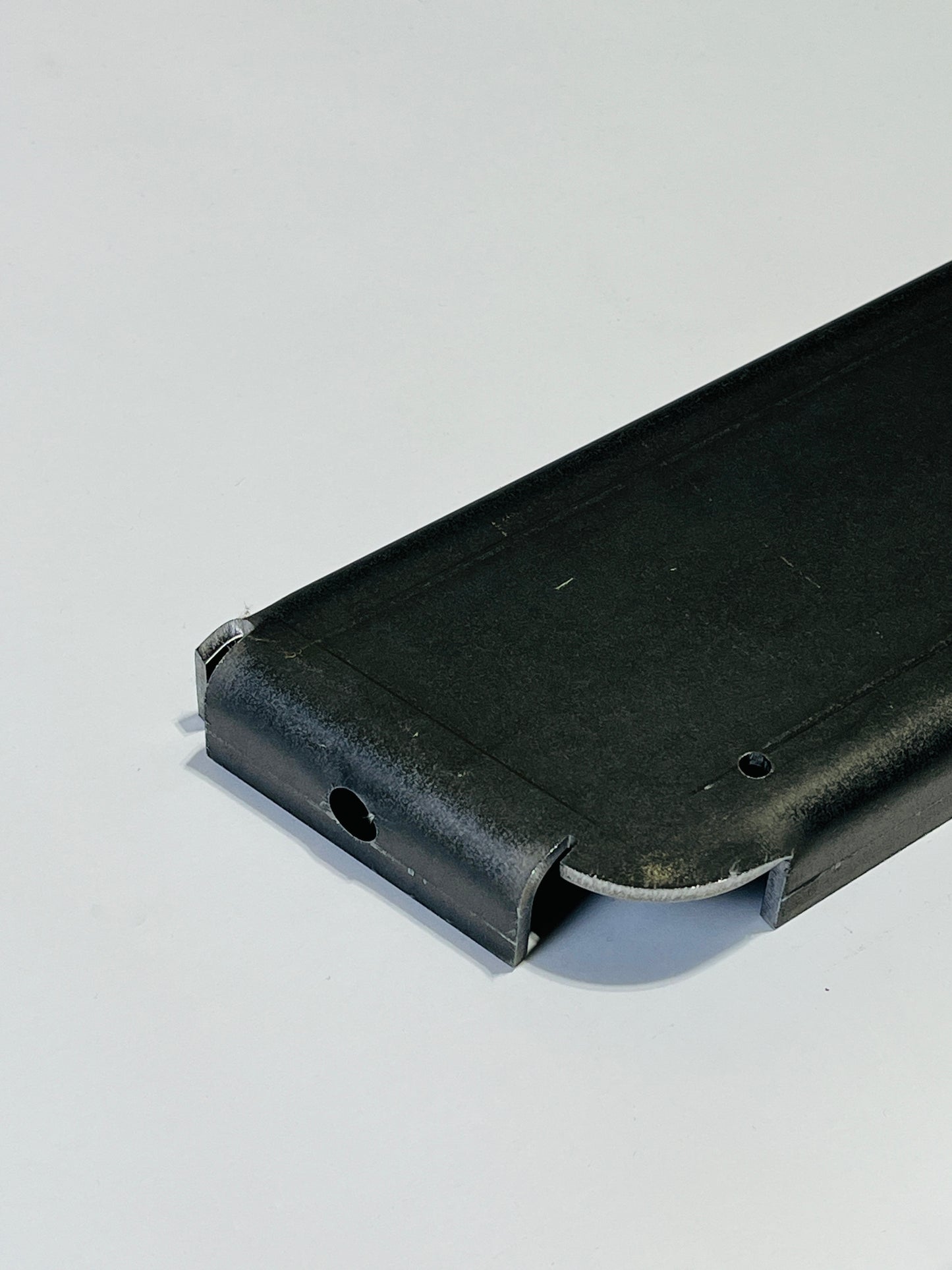

Assembly made easy

Weld yourself a finished product.

All our products are made quick to assemble and install with our intuitive design and easy to read instructions.

1. Align the tabs

2. Weld together

3. Install and done

Let's keep in touch.

Be the first to know about new parts and products and exclusive offers. Also, receive 5% off your next order when you sign up.